Table saw specifications usually quote a no-load rpm. I often receive questions about the importance of this figure and whether it matters when making a buying decision.

Quick Answer

In reality, while no-load saw rpm matters in saw design, this metric is not critical to the buying decision. There are other more important considerations which we will discuss further in this article.

This article will help you understand why table saw RPM is not the most important consideration when choosing a table saw. For those unsure of the meaning of rpm, please see the FAQs at the end of this article.

Why Blade RPM Matters To Saw Designers

When designing cutting implements, designers ensure the best cutting speed to produce the cleanest, most efficient cut to the material being worked. This speed measures the rate at which the cutting teeth pass through the material and is measured in feet-per-second (fps). For wood, the optimum speed range for general woodcutting is approximately 130 to 170 feet per second.

This range supports cutting harder materials at a slower speed and softer materials at a higher speed. For a circular saw blade, that feet per second speed is reached by a combination of blade diameter and blade revolutions per minute (rpm). Now, this is when we need to get into some simple algebra but stay with me, and I’ll guide you through it.

Blade Circumference

Let’s assume I have a 10-inch diameter blade; if I were to wrap a dressmaker tape around the outside edge, it would measure 31.42 inches. How do I know this? Because we are measuring the blade circumference, and if you remember back to your high school algebra, you get the circumference of a circle by multiplying pi by the circle’s diameter.

So, in this case, we multiply 10 x pi (which is 3.14159), giving us 31.42 inches. For an 8-inch diameter blade, the circumference will be 25.13 inches. Why does this matter?

If both blades complete one revolution simultaneously, the teeth on the larger-diameter blade will travel faster than the teeth on the smaller blade as they need to cover a greater distance. Therefore, the cutting speed of those teeth is higher. Put another way, the smaller diameter blade will need to be spun faster or have a higher rpm to give the same optimal cutting speed at the teeth.

Here Are Two Examples

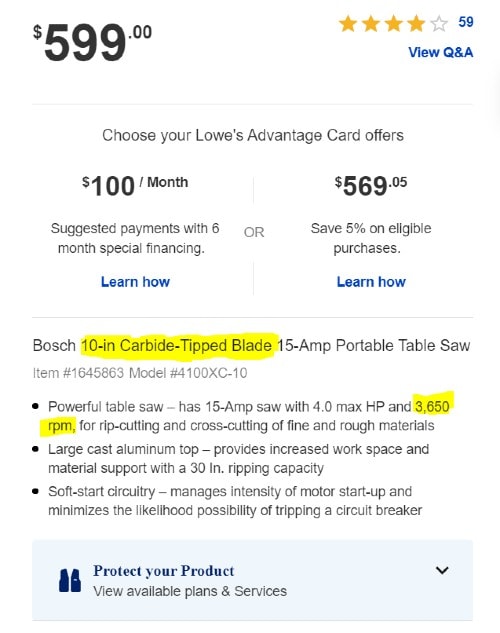

Example #1. The Bosch table saw advertisement below tells us the blade diameter is 10 inches and the no-load speed is 3,650 rpm.

Let’s work out the tooth-cutting speed:

10 inches x pi (3.14159) = 31.42 inches is the blade circumference

31.42 x 3650 rpm = 114,683 inches traveled by a tooth in one minute.

As we need feet per second, we divide this figure by 12 (12 inches to the foot) and 60 (60 seconds to the minute).

114,683 divided by 12 = 9,556 is the feet per minute

9,556 divided by 60 = 159 feet per second.

This combination of blade diameter and blade rpm gives us a 159 fps figure that sits nicely within the optimal cutting range for wood. If you remember, it was between 130 and 170 feet per second.

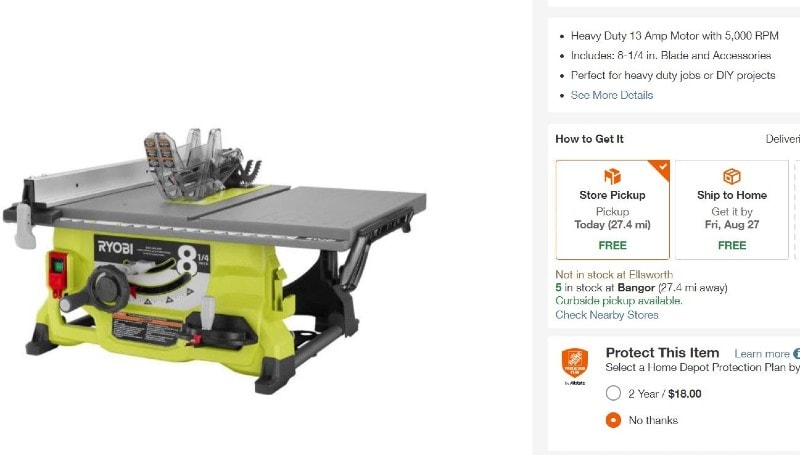

Example #2. The Ryobi table saw advertisement below tells us the blade diameter is 8.25 inches with a motor turning at 5,000 rpm, almost 40% faster than the Bosch. Let’s do the same calculation as above.

8.25 inches x pi (3.14159) = 25.92 inches is the blade circumference

25.92 inches x 5000 rpm = 129,590 inches traveled by a tooth in one minute.

129,590 divided by 12 = 10,799is the feet per minute

10,799 divided by 60 = 179 feet per second.

So this combination of a smaller diameter blade and a much faster rpm gives us a figure at the top range of the optimum speed for wood cutting.

From this, we see that designers calculate a table saw’s rpm to give the correct cutting speed for the timber likely to be cut on that machine. In and of itself, it has no real bearing on saw quality. Certainly not in the hobbyist and home user table saws.

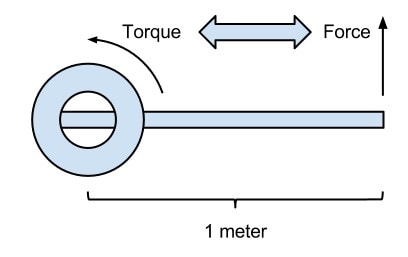

Let’s Talk Torque

A far more reliable measure of table saw quality is the power generated by the motor, not the speed. Why power? Well, from power comes torque. Torque is the rotating force produced by a motor’s spindle. The higher the power of the motor, the greater the turning force produced.

When you feed wood into a saw blade, the speed and force at which you push it onto the blade are important. With too much force or pushed too quickly, you load up the motor, potentially stopping the blade and throwing the work back toward you. This is a dangerous event called kickback.

If you don’t stop the blade with too much force, you will slow the blade down to a speed outside the optimal cutting speed, getting a poor-quality cut and possibly overloading the motor. Over time, this will shorten the motor life.

Therefore, the lower the power of the motor, the lower the torque. That means you will need to be more gentle feeding the wood onto the blade to maintain blade speed, ensuring a quality cut. If you’re doing a big job or using hardwood, you will take longer to accomplish your task.

In the previous advertisements, note that the Bosch motor is rated at 15 amps and the Ryobi at 13 amps. To work out the horsepower of those two motors, we multiply the amps by the voltage and divide by 746 to give horsepower.

So for the Bosch, 15 amps x 120 volts equals 1,800 watts. Divided by 746, this gives the Bosch a motor rating of 2.4 horsepower.

For the Ryobi, 13 amps x 120 volts equals 1,560 watts. Divided by 746, this gives the Ryobi a motor rating of 2.0 horsepower.

From this, we see that while both saws cut at the optimal cutting speed, the Bosch saw has two things going for it. The first is a larger blade, giving a greater depth of cut, and the second is a higher-power motor, giving greater torque. You can probably assume the Bosch will cost more than the Ryobi for these reasons.

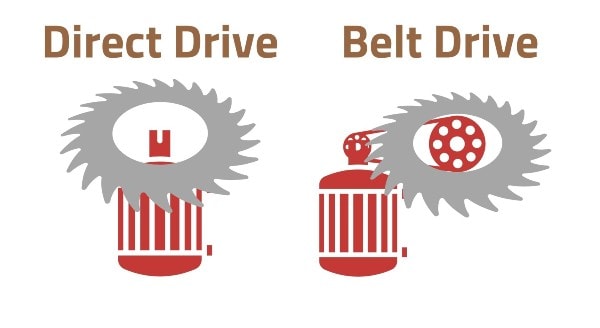

Why Are There Direct Drive And Belt Drive Table Saws?

A direct-drive saw is simple in that the blade is mounted directly to the motor spindle. These are found most often in the hobbyist and home user table saws.

Most of us don’t cut exotic timbers, plastics, mica, or metals. Therefore, the cutting range we discussed earlier is sufficient for the various woods we cut. The advantage of a direct drive saw is that it is compact, requires less maintenance, and is cheaper to build (and therefore buy).

Belt drive table saws are for those who need to cut a greater range of materials with different diameter saw blades. The motor drives the blade arbor through a system of belts and pulleys. This system is like a gearbox and allows a range of spindle speeds to be calculated for different blade diameters and material cutting speeds.

For example, cutting a polycarbonate sheet requires a fine-toothed blade at a cutting speed of 40 to 50 feet per second. Try that on your direct drive table saw, and you’ll either melt or shatter the polycarbonate. Yet, selecting a pulley ratio on a belt drive saw to suit the blade diameter and achieve the required cutting speed makes the job safe and straightforward.

The belt drive saws are more complex, bulkier, and more costly. For the majority of home users, they are not required.

Life Is About Compromise

If you’re like me, the table saw you want, and the table saw you can afford are two very different items. My suggestion is to understand your needs rather than your wants. Unless you are cutting exotic materials, ignore no-load rpm and choose a table saw that provides the necessary depth of cut with the greatest power that your budget can bear. I hope this article has been useful!